Spiral rollers

Spiral rollers: A spiral roller is a type of trailing roller composed of spiral-shaped bars or blades. This design provides good self-cleaning properties and is effective at breaking up soil clods, lightly compacting the soil, and creating a structured seedbed.

Spiral rollers

Spiral Rollers – RDM Parts for Effective Crushing, Compaction, and Residue Incorporation

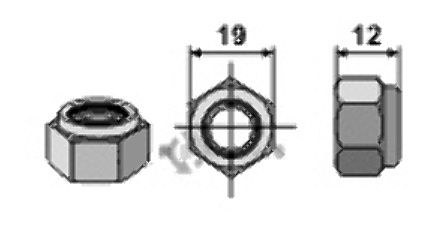

RDM Parts offers "Spiral rollers", which are a type of land roller or crumbler roller characterized by a series of spirally arranged bars or blades around a central shaft. These rollers are essential implements in modern agriculture, primarily used for seedbed preparation, breaking up clods, consolidating the soil, and incorporating crop residues. The spiral design offers several advantages: it provides a self-cleaning action, preventing soil buildup, and creates a more consistent crumbling effect across the working width. The spiral action also helps to reduce draft requirements compared to solid rollers. Spiral rollers are commonly found on cultivators, disc harrows, and combination tillage tools. Our spiral rollers are constructed from high-quality, robust steel, ensuring exceptional strength and durability to withstand the demanding conditions of field operations. The spiral bars are precisely formed and welded to the central shaft to ensure structural integrity and effective soil engagement. RDM Parts offers spiral rollers in various diameters, lengths, and bar profiles to match different soil types, residue levels, and machine designs. Investing in high-quality spiral rollers from RDM Parts contributes to improved seedbed quality, enhanced soil-to-seed contact, and efficient residue management, ultimately leading to better crop establishment and yield potential. The dynamic tool for soil refinement.

Contact

Contact RDM Parts for professional advice on selecting the right spiral rollers, ensuring effective crushing, compaction, and residue incorporation.